Product Description

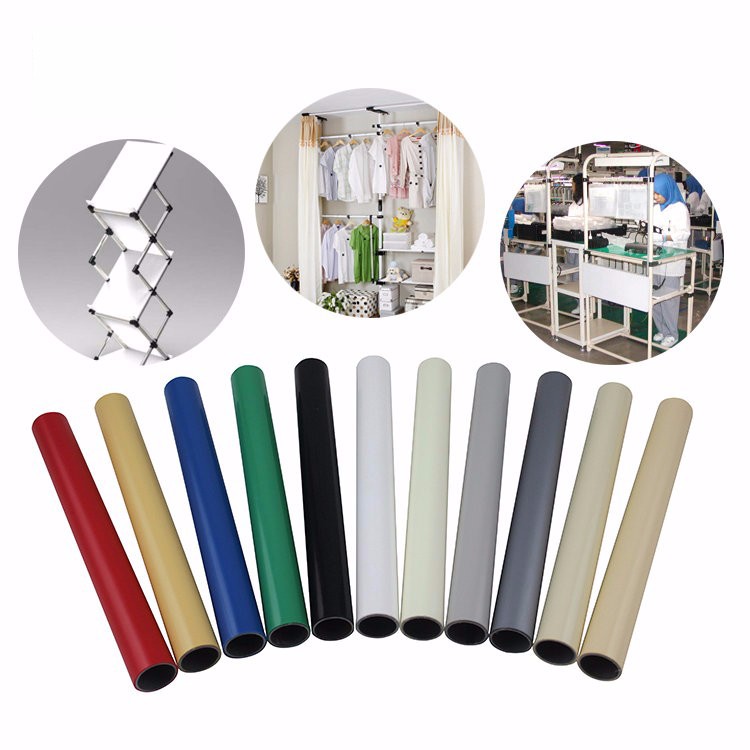

Production Line Flexible PE Coated Aluminum Lean Pipe Tube Bar ESD Pipe

Inside Pipe: Steel zinc plated

Outer coated Material: PE/ABS/PE-ESD

Pipe Diameter: φ28mm

Standard Length:4 meters/bar,or according to customers demand.

Standard color: White, Milk white, light yellow, black. Or red, blue, yellow,green,gray, any colors according the customer's demand

THE STRENGTH OF COATED PIPES

1)THE STRENGTH OF COATED PIPES

The procedure is for testing the center of a pipe

A. Simply Supported pipe.

B. Concentrated load on the center of the pipe

C. Speed of Loading: 1kg/min

D. Temperature: 20°c

__________________________________________________________________

Steel thickness 0.8mm

| DimensionA | Proportional Limit load |

| 450mm | Approx. 1275N |

| 900mm | Approx. 632N |

| 1,000mm | Approx. 520N |

| 1,100mm | Approx. 438N |

| 1,300mm | Approx. 395N |

| 1,500mm | Approx. 344N |

| 1,800mm | Approx. 288N |

Steel thickness 1.0mm

| DimensionA | Proportional Limit load |

| 450mm | Approx. 1593N |

| 900mm | Approx./ 790N |

| 1,000mm | Approx./ 650N |

| 1,100mm | Approx./ 548N |

| 1,300mm | Approx./ 493N |

| 1,500mm | Approx./ 430N |

| 1,800mm | Approx./ 360N |

Steel thickness 1.2mm

| DimensionA | Proportional Limit load |

| 450mm | Approx. 1911N |

| 900mm | Approx. 948N |

| 1,000mm | Approx. 780N |

| 1,100mm | Approx. 657N |

| 1,300mm | Approx. 591N |

| 1,500mm | Approx. 516N |

| 1,800mm | Approx. 432N |

Steel thickness 1.5mm

| DimensionA | Proportional Limit load |

| 450mm | Approx. 2404N |

| 900mm | Approx. 1193N |

| 1,000mm | Approx. 982N |

| 1,100mm | Approx. 877N |

| 1,300mm | Approx. 789N |

| 1,500mm | Approx. 649N |

| 1,800mm | Approx. 544N |

Steel thickness 2.0mm

| DimensionA | Proportional Limit load |

| 450mm | Approx./ 3104N |

| 900mm | Approx./ 1893N |

| 1,000mm | Approx./ 1682N |

| 1,100mm | Approx./ 1577N |

| 1,300mm | Approx./ 1489N |

| 1,500mm | Approx./ 1349N |

| 1,800mm | Approx./ 1244N |

Application

Application:

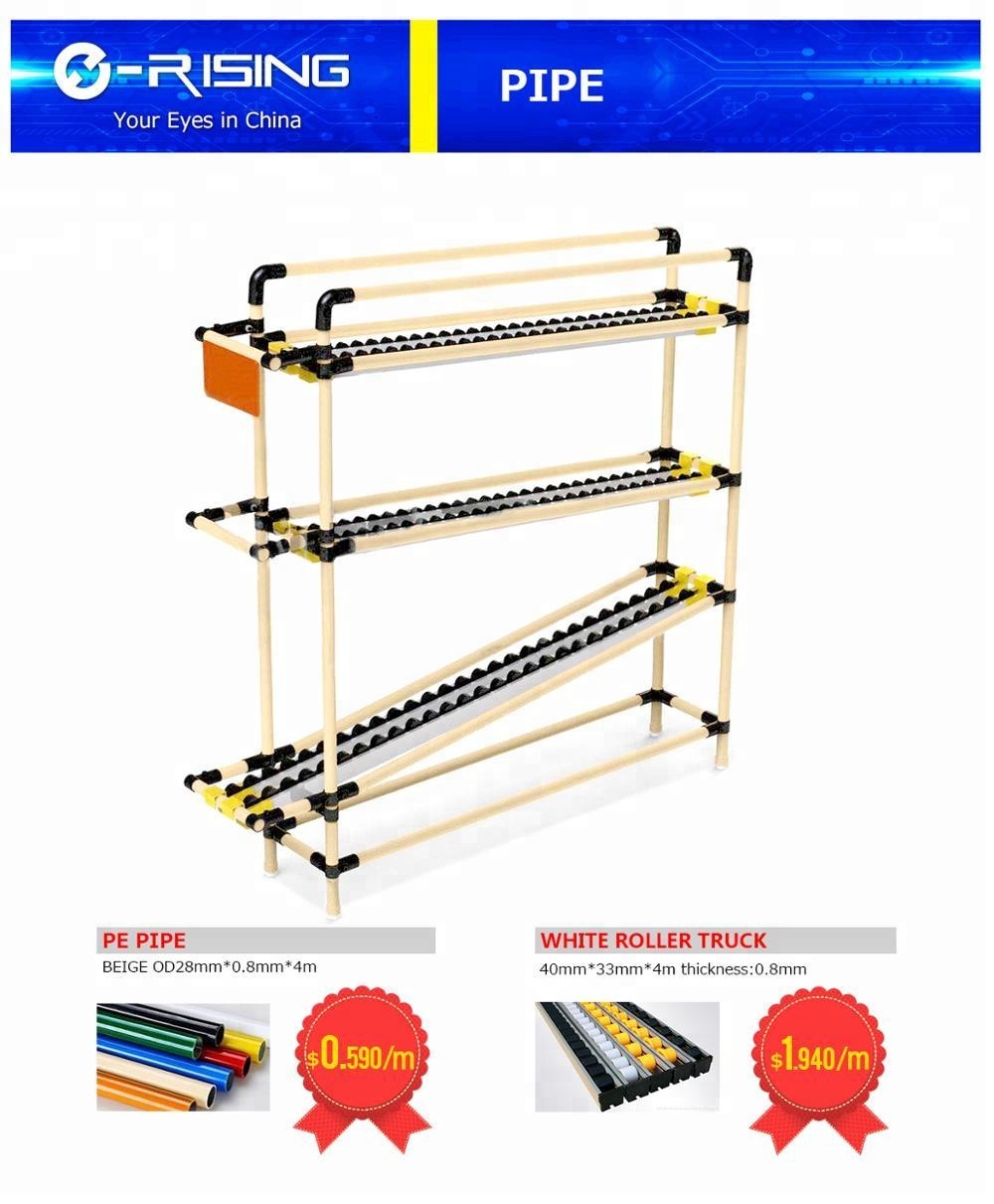

1.Various types of workstations or combinations of different unit production systems (lean mode of production)

2.Station equipment (production line assembly station or material input point of the distribution system)

3.Storage shelves (traditional multi-storey shelves, medium and light multi-storey first-in-first-out fluent shelves, shipping chute system, special application shelves)

4.Turnover, material vehicles (general multi-layer material loaders, non-general material distribution, temporary storage vehicles, specially designed mobile appliances)

5.Material rack (fixed type non-general material placement, temporary storage rack)

6.Commercial application (display rack, personalized display rack, creative display)